Dynamic Balancing in Preventive Maintenance: Benefits for Rotating Equipment Reliability

Rotating equipment ranges from industrial fans to turbines, which are critical in so many different areas of production. Unfortunately, most failures are due to vibration and imbalance. Dynamic balancing has become an important part of preventive maintenance strategies in order to ensure stability and longevity of operation. The following article illustrates five key benefits that machine balancing can offer for equipment reliability and a reduction of downtime.

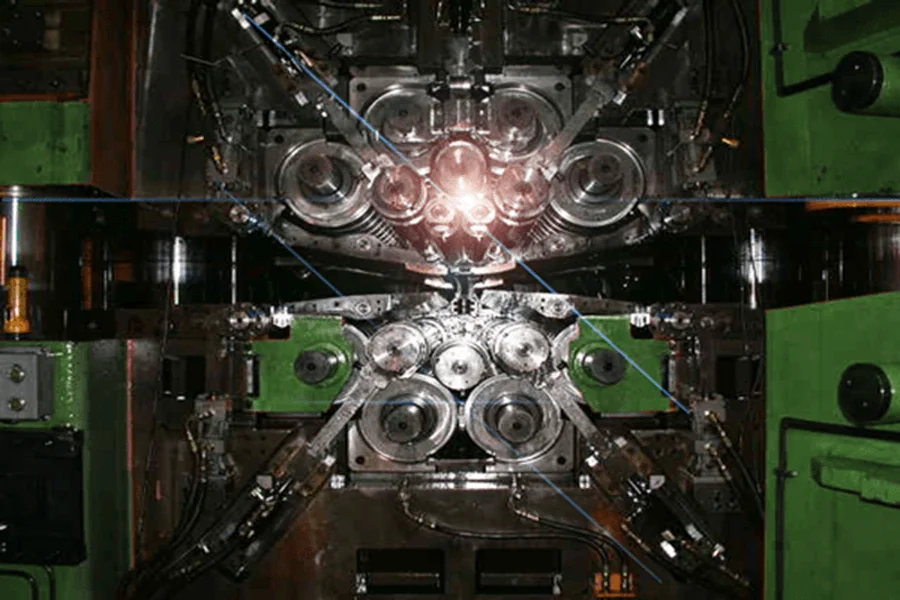

Reducing Vibration and Noise Levels

Vibration is caused by an imbalance in the rotating parts, which leads to the wear of bearings, shafts, and couplings. Dynamic positioning adjusts mass distribution in an effort to minimize vibration amplitudes over a broad range of operating speeds. Reduced vibration not only prolongs the life of such components but also reduces noise levels, hence making the working environment safer and more comfortable. This systematic approach towards imbalance helps the organization avoid cascading failures caused by continuous oscillatory forces and thus makes vibration control one of the essentials of good preventive maintenance. Over time, controlled vibration leads to smoother operations with reduced chances of emergency repairs. Additionally, reduced vibration can improve the accuracy of sensitive processes dependent on machinery stability.

Enhancing Equipment Longevity

Continuous imbalance increases the rate of fatigue and structural failure in equipment. Dynamic positioning ensures that rotating parts maintain consistent mass distribution, therefore inducing less stress on critical components. Lower mechanical loads on key components like bearings, gears, and seals extend their operational lifespan. This proactive approach enables maintenance teams to intervene according to the condition of the equipment rather than reactive repairs, which reduces lifecycle costs and improves return on investment. Longer equipment life, therefore, enhances overall plant reliability and production consistency. Increased longevity allows for better planning of capital expenditures and resource allocation.

Identifying the Cause of Premature Failure

Many rotating equipment failures mask other issues that occur repeatedly. Machine balancing allows for the determination of whether misalignment, uneven wear, or the accumulation of foreign material is a factor in early failure. If an imbalance source can be identified, maintenance teams can take action against the root cause. Businesses that invest in reliable dynamic balancing services that provide comprehensive diagnostics gain deeper insight into recurring problems. Root causes being dealt with disallow repeated breakdowns and help to reinforce reliability in the long term, reinforcing the importance of condition-based monitoring with the balancing practice. Finding these causes early allows maintenance teams to implement long-term solutions instead of temporary fixes. This proactive analysis also minimizes unscheduled downtime and other secondary damages due to undetected faults.

Improving Energy Efficiency

Unbalanced machinery requires more power to maintain functional speeds, increasing energy consumption. In discrepancy, duly balanced rotors work much more efficiently to reduce electrical demand and minimize heat generation both in motors and drive systems. Over time, similar effectiveness translates into measurable cost savings while reducing the environmental impact. Energy-effective operation further reduces the possibility of thermal-affiliated failures, therefore helping towards smoother, interruption-free product cycles. Dropped energy consumption aids installations in achieving their sustainability pretensions and cuts functional carbon footprints. Also, associations optimizing energy effectiveness can achieve better compliance with industry regulations and environmental norms.

Enhancing Safety and Operational Stability

Vibration-induced instability can put machinery and personnel at risk. Excessive wobbling or resonance may lead to the sudden failure of a mechanical component, giving way to accidents. Dynamic positioning stabilizes rotating elements and reduces such catastrophic incidents. Correct balancing also means your equipment operates within set tolerances, avoiding operational disruptions that might affect sensitive processes. Where precision and consistency are indispensable, maintaining stable rotations will definitely support regulatory compliance and worker protection as well. Consistently safe operations enhance machinery performance and reduce insurance and liability concerns. Well-maintained equipment instills a safety culture in your employees, ensuring that they follow the best practices during operation

Dynamic balancing extends beyond a mere technical adjustment; it is a strategic tool in preventive maintenance that enhances reliability across rotating machinery. It reduces vibration, prolongs the life span of components, identifies the root cause of failure, improves energy efficiency, and advances operational safety. Businesses, therefore, can ensure more consistent performance with reduced maintenance costs. Regular dynamic positioning ensures that the rotating equipment performs at optimum efficiency, reaffirming productivity and long-term resistance. Organizations that practice machine balancing reinforce operational stability and build a culture of proactive maintenance.